THE NEW FRONTIER IN ALUMINUM SCRAP PROCESSING

Laser-Induced Breakdown Spectroscopy (LIBS) is an advanced laser technology used for the analysis and identification of metal pieces in their different chemical compositions and alloys. A LIBS sorter fires a high-energy laser pulse onto the material’s surface. The pulse creates a microplasma, whose emitted light characterizes the chemical composition of the metal in its different elements and is analysed by sensors performing a few milliseconds breakdown spectroscopy.

LIBS is a complementary technology to X-ray transmission, which does not perform any chemical breakdown analysis but sorts metals and metal alloys based on their different densities.

LIBS is also a complementary technology to X-ray fluorescence, which also performs a chemical breakdown analysis but presents limitations in performance on light metals like Magnesium and Aluminium alloys because of the low energy of the light they emit under the XRF source.

Although LIBS can do what XRT and XRF do, those technologies are complementary to LIBS because the capital cost of a LIBS sorter on a per-ton-per-hour capacity is quite higher than that of XRT and XRF sorters, making the cascade of those different technologies a more convenient solution.

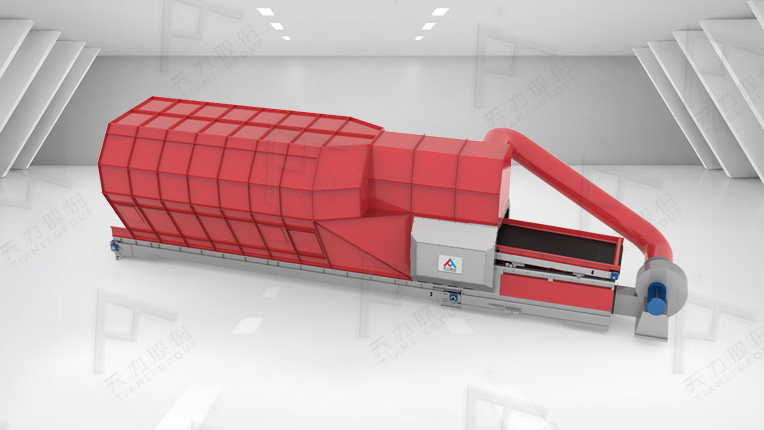

High-speed laser scanning

As the scrap moves along the conveyor, high-speed 3D laser scanners measure the surface and geometry of each piece and direct the LIBS laser on the X/Y coordinates of the piece and adjusts the auto focus to its Z-axis.

Laser cleaning and analysis

Once the X/Y/Z coordinates are set, the Cleansort module performs two key functions:

Laser Pre-Ablation:

The system cleans the surface by removing contaminants, coatings, or rust,exposing the underlying material for analysis.

LIBS Measurement:

The laser induces a plasma on the surface of the material. Doing the breakdownspectroscopy of the plasma, material is identified in its exact metal composition,

distinguishing not only between metals like steel and copper but also between alloy groups,

such as 5000 and 6000 series aluminum, and even between similar alloys like 6010 and 6016.

Higher Value per Ton

Innovative data analysis and computing process offers the option to optimize

the material sorting even further by creating a product that is as close as possible

to the desired alloy composition. This new approach can potentially double the

added value of your sorted material.

TEST US NOW

Test the performance of our sorters with your own material.

Our worldwide team is ready to answer your questions and collaborate with you

to identify the optimal sorting solution for your needs.