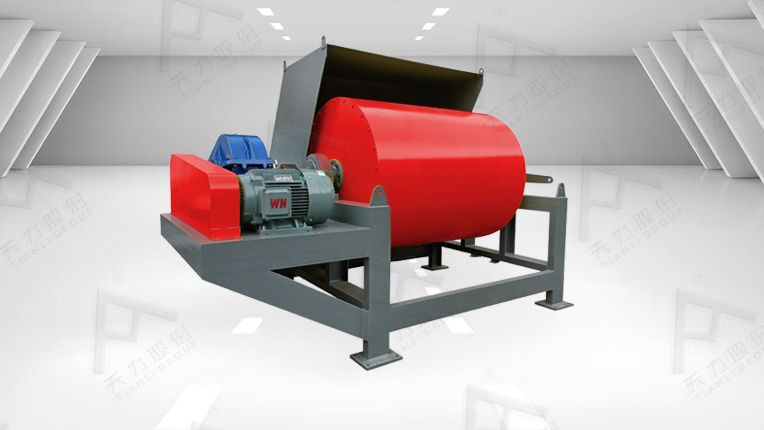

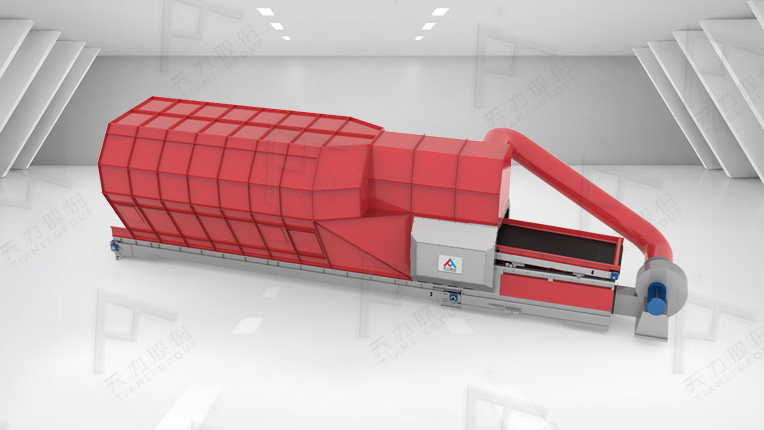

Magnetic Separator TLYL serious with dry process feature.

【Scope of Application】:

● Lean iron ore after primary crushing or medium crushing coarse separation, remove part of waste rock, sand and mud, in order to reduce the working process (such as grinding, etc.) load, greatly improve its productivity, reduce energy consumption;

● The separation of iron ore before smelting can improve the grade of ore, and the recycling of scrap steel slag in steel works

● Low grade iron ore purification, hematite reduction in the process of closed-circuit roasting, the raw ore not fully reduced will be selected and returned to re-burning

● Iron removal and purification for materials in foundry, ceramics, coal and other industries

The cases recently: