Tianli Equipment Technology

USA. Motor shredders recycling plant site

- CRAFT:马达破碎分选行业解决方案

- PRECISION:分选精度可达98%

- OUTPUT:处理量3-5T/h

- SITE:美国

In early 2019, a US customer ordered a eddy current separator for metal separation of motor shredders. The equipment brings great convenience to the customer, allowing the customer to effectively separate copper and aluminum, so that copper and aluminum waste can be reused, to achieve the purpose of significant revenue generation.

The following two pictures are the material photos before and after separation respectively:

Before After

This plant line is different from the sorting line of ASR recycling or household garbage recycling. The sorting line of ASR material is generally from the waste to recover copper, aluminum, zinc and other non-ferrous metals, the remaining materials are treated separately; For the sorting line of this customer, the motor is first broken into fine materials with the help of crusher. Then, because the copper wire is fine material, the aluminum block is relatively large, so the customer uses our high-frequency eddy current sorting equipment to successfully separate aluminum and copper.

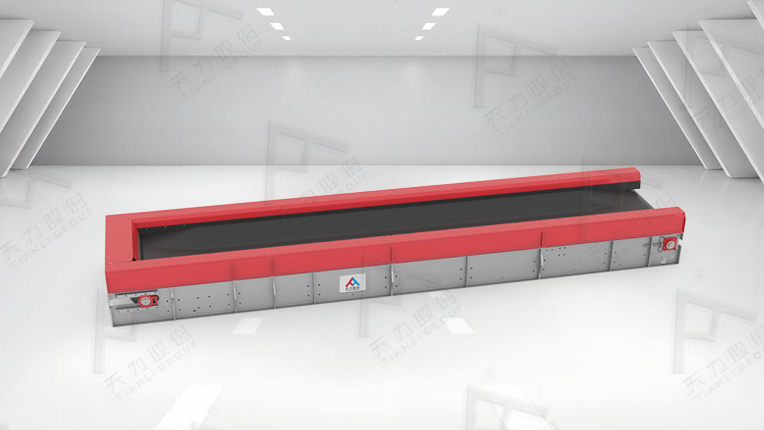

Customers in addition to order our eddy current sorting machine, also purchased belt machine, high magnetic separator and other supporting equipment.

After one month of production time, we will deliver the sorting equipment to the customer as scheduled; After the customer receives the goods, after a week of installation and debugging for trial operation.

The customer's processing capacity is about 3-5t /H. At present, the sorting line of the customer runs smoothly, and the expected production capacity has been completed for the customer. The client also has plans for capacity expansion and is currently planning the project.

Tianli eddy current separator, the introduction of German technology, unique magnetic roller design, so that the sorting area of the magnetic energy to reach the strongest; The 22+ multi-pole design and magnetic roll speed of up to 3000 RPM allow vortex current to have the highest sorting frequency, exceeding the competition, thus achieving effective separation of fine metal (difficult). If you have metal sorting problems, welcome customers to consult.