The invention of the plate magnetic separator can completely solve the industry in addition to the high standard of iron requirements, but its cost is only one tenth of the vertical ring type high gradient magnetic separator, its high cost performance makes the vertical ring type magnetic separator will never be beyond the possibility. Fundamentally solve the traditional magnetic separator in the processing of small granular materials easy to clog and serious material with the worldwide technical problems, in the field of high gradient magnetic separator is a revolutionary breakthrough, the performance is the world's leading.

【Applicable Materials】:

TLGP plate magnetic separation machine is mainly suitable for less than 5 mm size of weak magnetic mineral ore and non-metallic mineral of iron, such as: mica powder, quartz sand, potassium feldspar, nepheline, fluorite, sillimanite, spodumene, kaolin, manganese ore, weak magnetite, pyrrhotite, roasted ore and ilmenite, hematite, limonite and siderite, ilmenite, chromite, wolframite, tantalum niobium, red mud, etc. Can also be used for coal, non-metallic ore, building materials and other industries in addition to iron operations.

【Working Principle】:

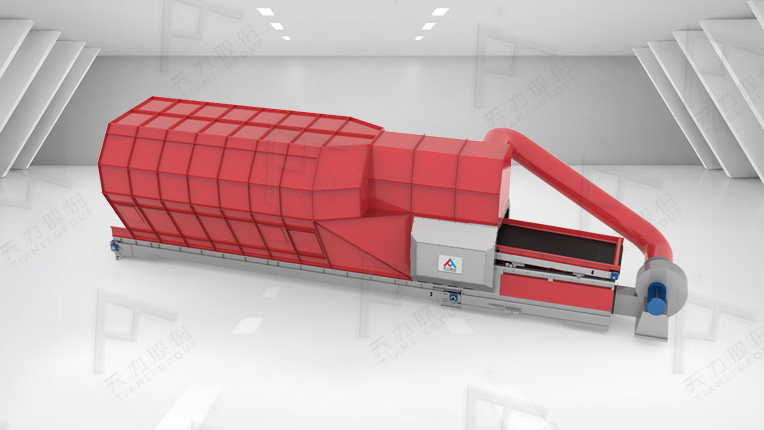

TLGP plate magnetic separator is mainly composed of bracket, plate magnetic separation system, feeding mixing system, water source system, iron unloading system, regulation system and other structures. When working, the material flow direction and the iron unloading system form the reverse countercurrent type, the non-magnetic material uses the principle of physical structure to self-flow to the discharge port, and the purpose of complete discharge is achieved by unloading and washing. The magnetic material is absorbed by the super strong magnetic field over a long distance, in a long area and for many times. The magnetic material runs in the reverse direction of the iron unloading system to the iron outlet and is completely unloaded after the ore unloading and washing.

【Product Advantages】:

● TLGP plate magnetic separator magnetic system adopts advanced computer simulation design, the repulsive magnetic pole arrangement structure, effectively protect the maximum adsorption area and adsorption capacity of iron within the working range.

● Magnetic materials are all made of high-strength rare earth NdFeB with high purity, large dosage and strong magnetic force. The highest magnetic field strength can reach 15000GS. In the field of high gradient magnetic separator is a revolutionary breakthrough, the performance of the world's leading. Optimal design of the whole machine, the magnetic system adopts the fully sealed structure, anti-oxidation, to ensure that the magnetic force consumption of the strong magnetic core in the bad environment within ten years is not more than 5%, can be used normally.

● The driving part adopts stepless speed-adjusting motor with excellent performance, which can work continuously and unload iron fully automatic, saving manpower and running reliably without trouble. The feeding system of the whole machine adopts the structure of motor stirring, so that the material into the magnetic separation area uniform and pulp concentration to meet the requirements of mineral processing, the separation effect will be more effective and satisfactory.

● The water source system of the whole machine adopts a single water inlet, and the water point is controlled by separate valves. It is convenient for customers to form a complete set of water supply equipment. The valves can be opened and adjusted according to actual needs.

● The parts through or in contact with the material are all made of stainless steel or non-magnetic material, which can effectively avoid the secondary pollution of the material caused by the mechanical iron of the equipment. Depending on the mineral, the important parts will be treated with wear resistance. The structure of the whole machine can also be made according to the field conditions of open structure or fully sealed structure. Can adapt to different customers and various requirements of the site.

The cases recently: