【Advantages】:

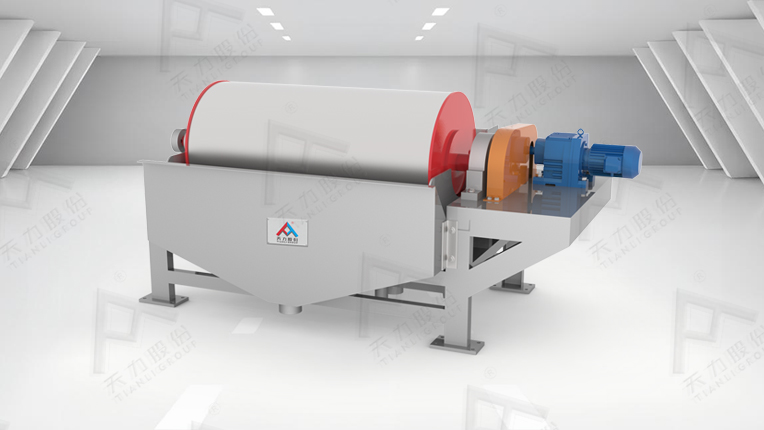

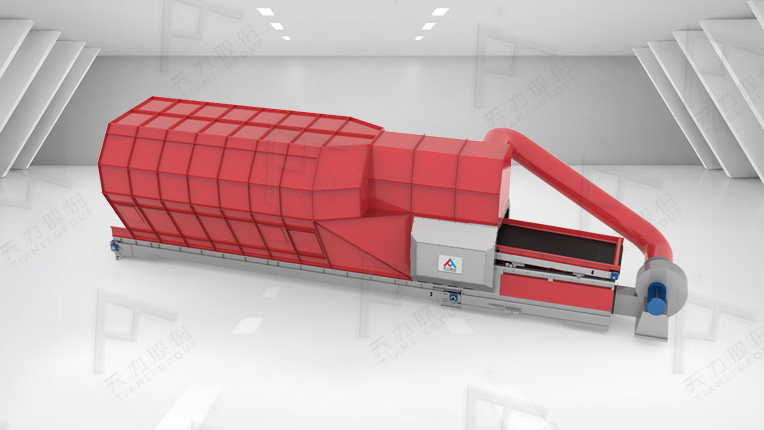

● There are silt discharging devices on both sides of the tank to facilitate the clearing of silt in the tank

● Magnetic system using reliable fixed scheme, to ensure that the magnetic group will never fall off and damage, trouble-free operation

● Duck bill type flushing pipe, strong adaptability to water quality, high water pressure, effective water saving 50%

● Magnetic materials are made of magnetic materials with high remanence and high coercivity, which have very good anti-demagnetization ability, and demagnetization is less than 5% in eight years

● The protection of the cylinder has four ways for customers to choose: adhesive protection, efficient stainless steel protection, wear-resisting ceramic protection and ultra-high molecular wear-resisting material protection

【Scoup of application】:

CTS Series concurrent wet drum magnetic separator is specially used for preseparation coarse-grained ore, such as river sand, sea sand and other coarse-grained sand. At the same time, it is suitable for recovering magnetic heavy medium.

CTB series semi-countercurrent wet drum magnetic separator is suitable for stage separation operation in the grinding and separation process of the concentrator, which can obtain higher concentrate quality and metal recovery rate, and is widely used.

CTN series counter-current wet drum magnetic separators are suitable for roughing and sweeping operation of fine and strong magnetic ore. After a long separation area, the metal recovery rate in the tailings is high.

Customer site: